Digitise Pharma

Transform your pharmaceutical manufacturing with AI-powered smart analytics

REACTOR ROOMS

Did a batch fail? Why did it happen? When did it happen? What were the events that could have warned that a batch was about to fail? Was the cooling/heating curve maintained?

These are all questions that can be answered by using our smart analytics platform. You will get access to real-time and historical data on batches running in reactor rooms.

By placing sensors, we are able to digitise all the processes running in reactors. Real-time data on the temperature, pressure, vacuum and other process parameters are captured, thereby making sure that the recipes are being followed to the highest standards.

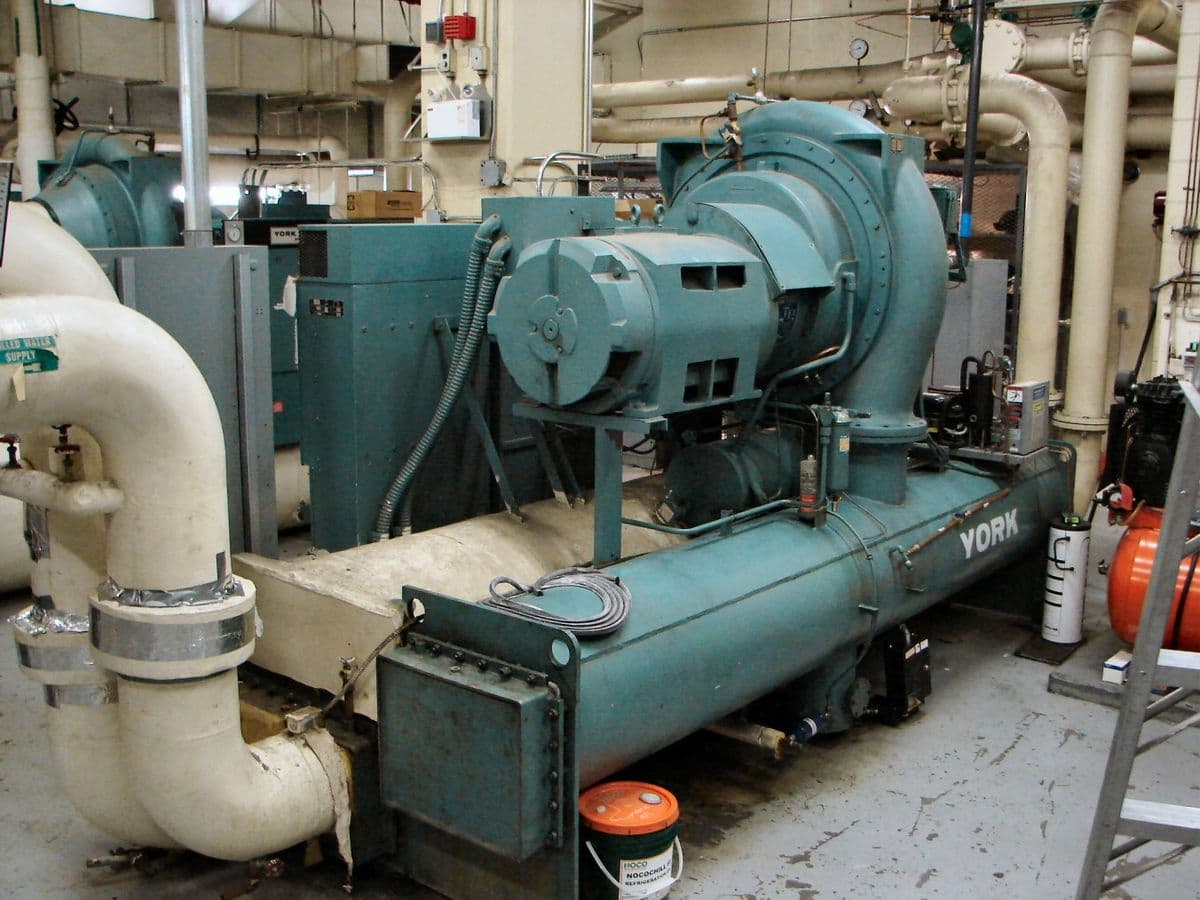

UTILITY ROOMS

Utility rooms act as the heart of the industry, supplying the required utilities such as steam, chilled water, vacuum, pressurised air, etc., which are critical for the proper operations of the pharmaceutical industry.

Sudden unprecedented drops in the supply of any of these will result in the bottlenecking of reactor operations in the plant premises, thereby reducing yield quantity and quality.

On average our clients have seen their utilities improve to more than 90% adherence to demand.

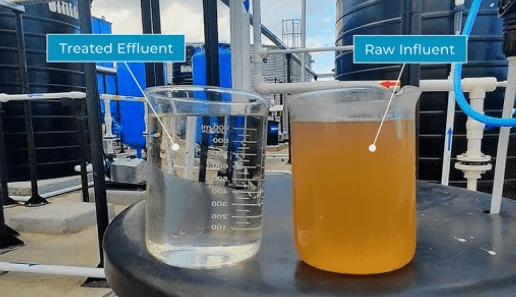

EFFLUENT TREATMENT PLANTS

Just as utility rooms are critical to ensure the pharma reactors are functional, effluent treatment plants or ETPs, are critical to process the waste byproducts of the chemical reactions.

Our systems monitor the impurity levels of treated effluent, including pH, BOD, COD, TSS, Ammonia, Nitrate, Chlorine, etc.

This ensures less harm to the environment and reduction in water pollution.

Our Clientele