Digitise Brewery

Transform your brewing operations with AI-powered smart analytics and real-time monitoring

FERMENTATION TANKS

Brewers thrive on control and consistency. A single misstep can be the difference between a great batch or a substandard one. The urge to check, double check and triple check is real.

With our smart analytics platform you will be able to monitor and regulate Temperature, monitor Pressure, Specific gravity, pH, DO in real-time. Our AI-driven analytics deliver actionable insights helping new and existing breweries digitise, modernise and most importantly give peace of mind to Brewers.

BATCH CONSISTENCY

Customers trust your brand and brew to deliver. Nobody likes to have a beer that tastes funny or unfamiliar in some way. A single bad batch can send the brand value out the window. Manual sampling steals your time; Insights are restricted by fermentation data that lives in notebooks.

With our AI insights every batch becomes more predictable and more profitable. By understanding the trends and analysing historical data, batch to batch consistency improves in a scientific manner.

Keep track of your batches and flavour profiles easily by digitising them. Trying a new recipe? Get detailed records on the entire fermentation process, revisit the recipe, make few changes – everything is logged for your convenience and insight.

UTILITIES

Beer brewing is a science transforming raw ingredients into liquid gold. Behind this captivating process lies a critical foundation that might go unnoticed: the utility requirements - providing essential inputs such as water, electricity, steam, natural gas, compressed air, and refrigeration.

Water quality and quantity are essential factors in brewing. This element constitutes your beer's composition, taste, and consistency. Checking pH, mineral content, etc.

Compressed Air is useful for moving ingredients, cleaning, and bottling. Any bottling issues might cause (pun intended) Bottleneck problems!

With complete visibility into each utility, breweries can anticipate demand and ensure that resources—whether compressed air or steam are available when needed. Early detection of utility fluctuations allows brewers to intervene before they impact processes, proactive rather than reactive.

POST PRODUCTION

As a Master brewer after painstakingly ensuring each parameter is in order, what if your distributers don't maintain SOPs? Once again, your brand value goes for a toss….

We monitor your supply chain and distribution points to ensure that your brew is being kept at the right temperature so that it tastes exactly as it did when it left your facility. Any distributers trying to cut corners with sub-par refrigerators can't do that to your product!

REGULATORY REQUIREMENTS

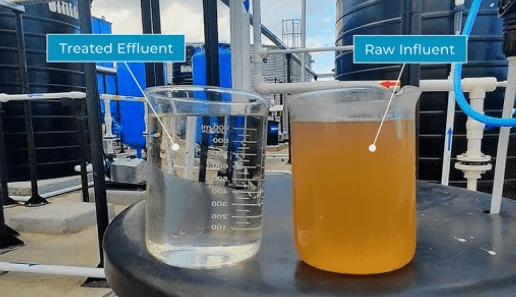

Breweries must adhere to local and national regulations related to brewery utility requirements and environmental standards. Effluent release is regulated according to the notification of the Ministry of Environment, Forest, and Climate Change.

Our systems monitor the impurity levels of treated effluent, including pH, Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), Total Suspended Solids (TSS), Ammonia, Nitrate, Chlorine, etc.

Ensuring that your manufacturing plant is compliant with the Pollution Control Board's requirements. This ensures less harm to the environment and reduction in water pollution.

Our Clientele